cmpAPC

Features

cmpAPC impresses with its modern design and user friendly user interface. The user can navigate between all features easily since the well structured architecture.

- General

cmpAPC offers APC functionalities for the engineer and production in the CMP area of semiconductor production.

The calculation of the polishing times is fully automatic. The engineer can control and check every detail of the prediction. Extensive analysis possibilities give the user an overview of the process.

R2R solution for CMP

Calculate startup values for CMP tools to optimize the process. The extension is a 1-channel optimizer for the removal rate. Pad and head ages are subjecct for monitoring and advanced control models.

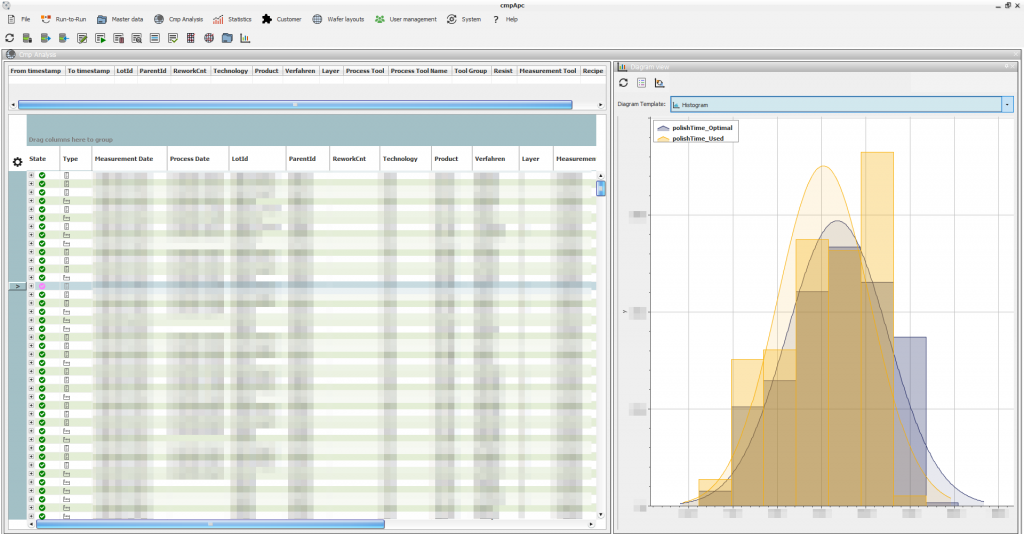

Comfortable user interface

cmpAPC is available as a separate PlugIn for the BlueLine UI framework. It offers extensive possibilities to analyze and configure the CMP process.

cmpAPC offers APC functionalities for the engineer and production in the CMP area of semiconductor production.

The calculation of the polishing times is fully automatic. The engineer can control and check every detail of the prediction. Extensive analysis possibilities give the user an overview of the process.

Master data and parametrization

APC completely is configurable by master data. Any master data item can be an action or a control information like wafer layout, target set, parameter model.

Every master data item can be parametrized. The parameters can be defined in lookup tables or can be requested from an external data source. The user has the full flexibility to setup and control the parametrizeation for the whole process with minimal effort.

cmpAPC offers APC functionalities for the engineer and production in the CMP area of semiconductor production.

The calculation of the polishing times is fully automatic. The engineer can control and check every detail of the prediction. Extensive analysis possibilities give the user an overview of the process.

- Standard

Full inline integration

cmpApc is full integrated into the production line. On request (MES, automation) the module provides the optimal polish time for the next carrier. The system stores all used information, measurement results and tool counter as basis for further prediction.

Detailed CMP controller setup

The R2R controller for CMP can be defined in all details like the optimizer weighting, filter setting, constraints and the impact of aging.

R2R levels allow the fine grade setup of the calculate of startup values.

Full data management included

Statistics

cmpApc contains a powerfull statistics engine, which allows to visualize the available data in various diagram types.